Image 1 of 1

Image 1 of 1

Resin Injection

What is Resin Injection?

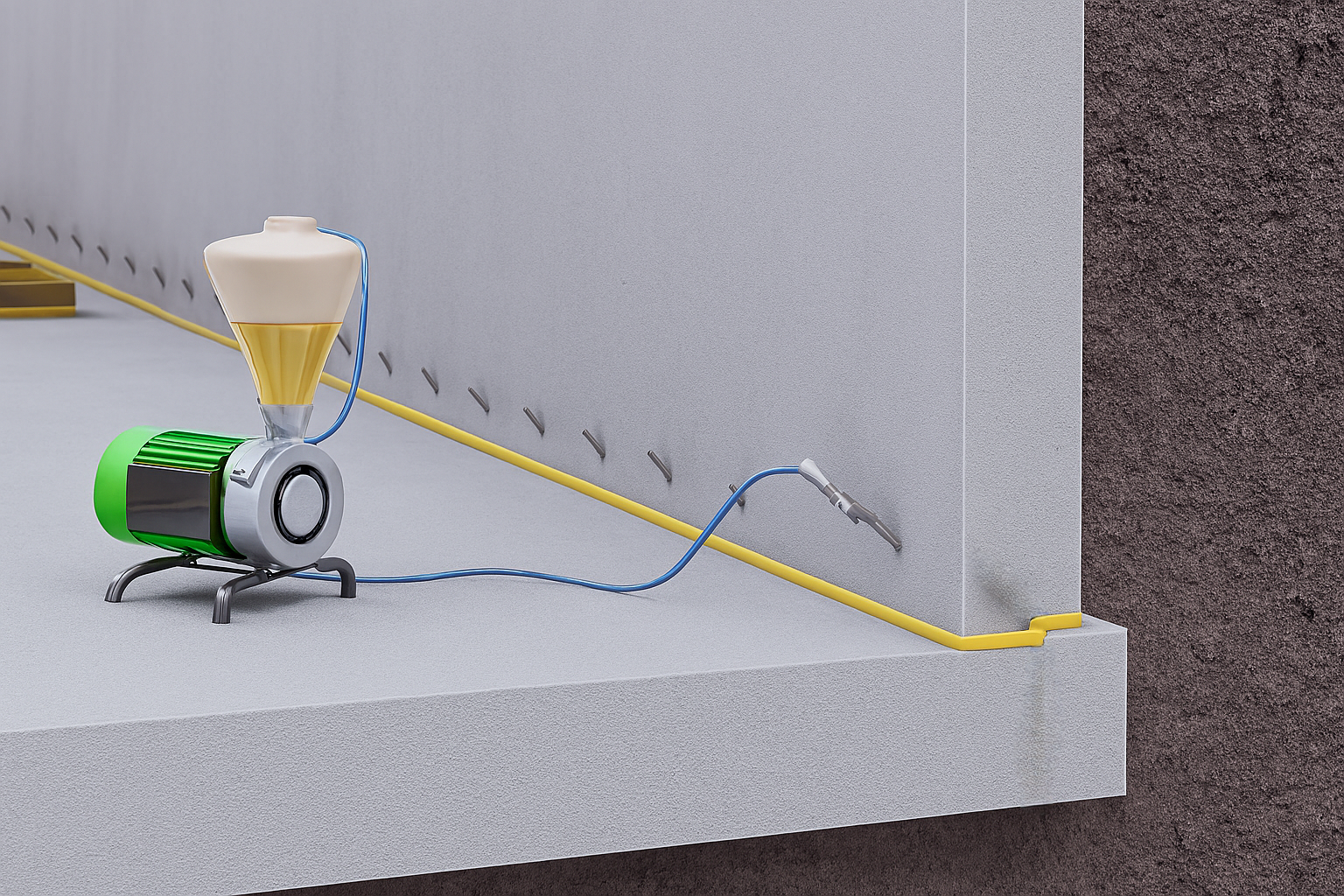

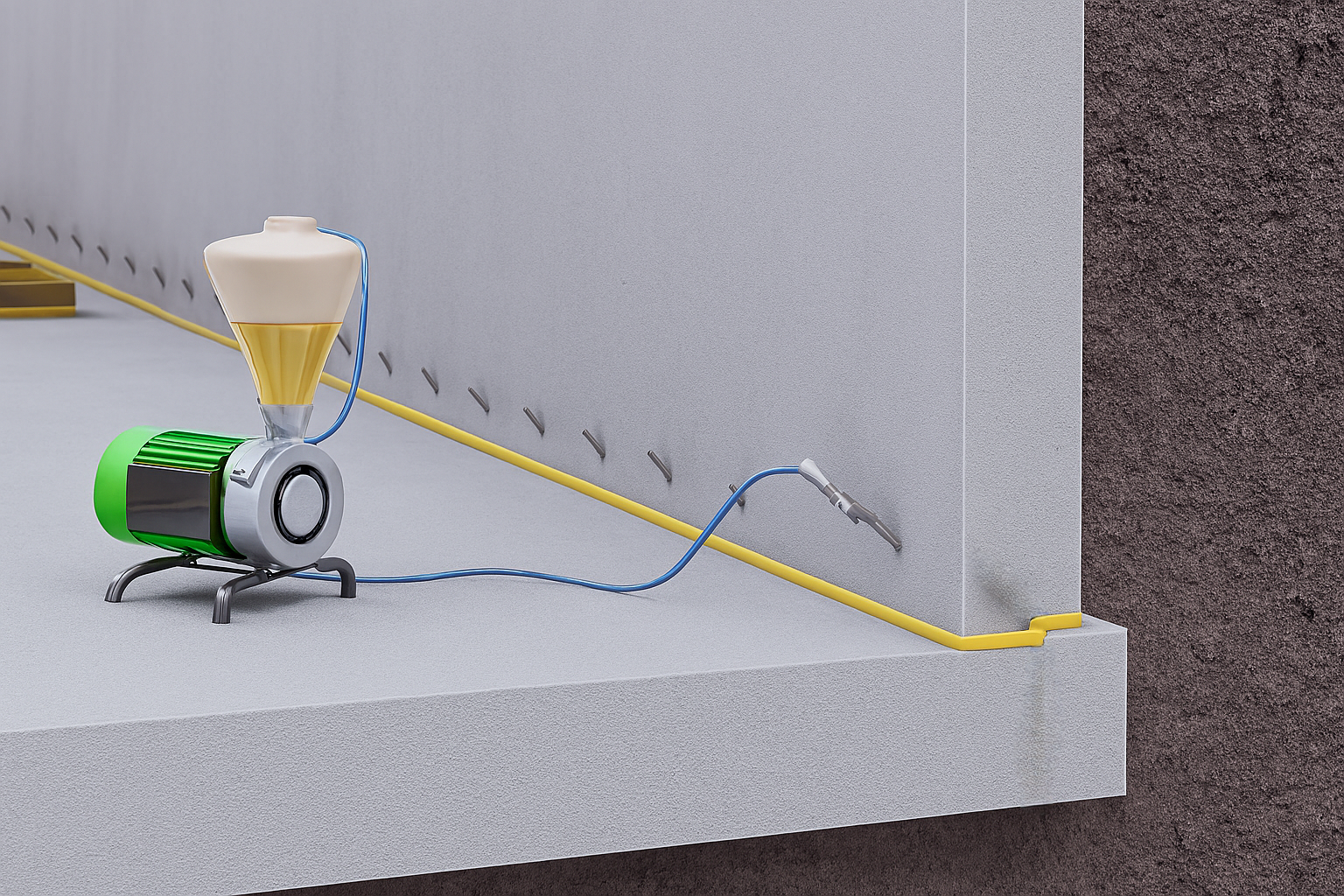

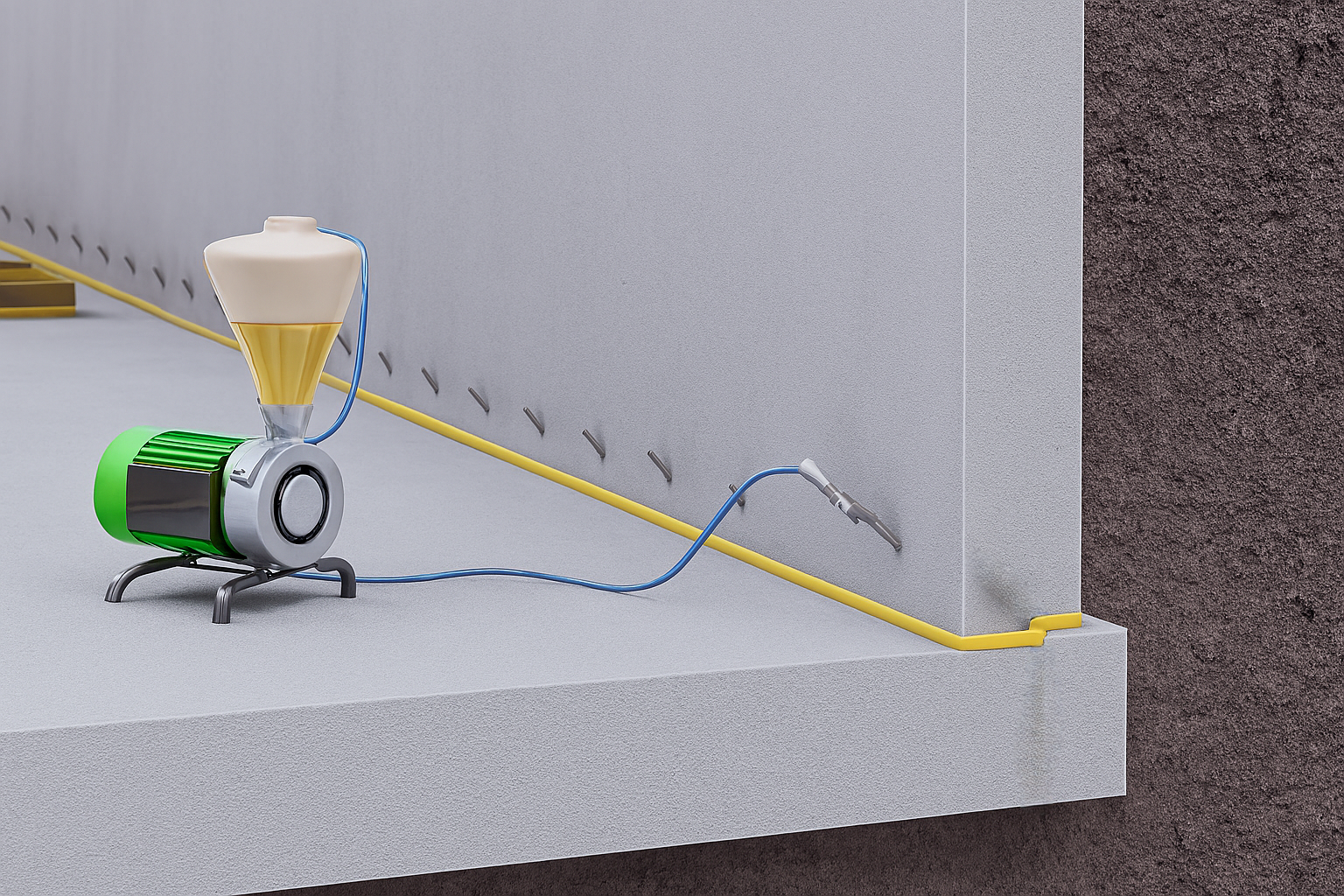

Resin injection is a precision technique used to seal leaks, fill cracks, stabilise foundations, and create dry environments in below-ground structures. By injecting specialised resins into concrete or masonry, we restore integrity and prevent water ingress, without excavation or disruption.

In simple terms: resin injection is like giving a concrete wall or floor a “filling” to stop leaks and/or strengthen it. We drill small holes, place special valves (called packers), and then pump liquid resin into the cracks or voids. The resin flows through the gaps, reacts, and hardens, sealing leaks, bonding the structure, or stabilising the ground beneath.

At first glance, resin injection may look straightforward: drill a hole, pump in resin, and let it harden. In reality, it’s a highly specialised process that demands expert knowledge of both the materials and the structure being treated.

• Understanding the structure: Every building or tunnel behaves differently depending on age, construction method, and the forces acting on it. An expert must assess whether cracks are structural or superficial, whether water ingress is under pressure, and how the substrate will respond to injection.

• Choosing the right resin: Polyurethane, epoxy, acrylic, and silicate resins each have unique properties. Selecting the wrong material could mean a temporary fix that fails under stress, or worse, causes further damage.

• Applying the correct technique: Injection pressure, packer placement, and resin volume all need careful control. Too much pressure can widen cracks; too little may leave voids unfilled.

• Ensuring long-term performance: The goal isn’t just to stop a leak today, it’s to create a durable, watertight, and structurally sound solution that stands up to years of use.

What is Resin Injection?

Resin injection is a precision technique used to seal leaks, fill cracks, stabilise foundations, and create dry environments in below-ground structures. By injecting specialised resins into concrete or masonry, we restore integrity and prevent water ingress, without excavation or disruption.

In simple terms: resin injection is like giving a concrete wall or floor a “filling” to stop leaks and/or strengthen it. We drill small holes, place special valves (called packers), and then pump liquid resin into the cracks or voids. The resin flows through the gaps, reacts, and hardens, sealing leaks, bonding the structure, or stabilising the ground beneath.

At first glance, resin injection may look straightforward: drill a hole, pump in resin, and let it harden. In reality, it’s a highly specialised process that demands expert knowledge of both the materials and the structure being treated.

• Understanding the structure: Every building or tunnel behaves differently depending on age, construction method, and the forces acting on it. An expert must assess whether cracks are structural or superficial, whether water ingress is under pressure, and how the substrate will respond to injection.

• Choosing the right resin: Polyurethane, epoxy, acrylic, and silicate resins each have unique properties. Selecting the wrong material could mean a temporary fix that fails under stress, or worse, causes further damage.

• Applying the correct technique: Injection pressure, packer placement, and resin volume all need careful control. Too much pressure can widen cracks; too little may leave voids unfilled.

• Ensuring long-term performance: The goal isn’t just to stop a leak today, it’s to create a durable, watertight, and structurally sound solution that stands up to years of use.